Understanding the U Shape Ditch Lining Machine and Its Core Components

Key Structural Elements of the U Shape Ditch Lining Machine

The U Shape Ditch Lining Machine comes equipped with a heavy duty steel frame plus a dual axis trenching system that helps maintain uniform depth throughout the digging process. Key parts of this machine are worth mentioning: there's the mold die capable of handling depths up to 300 mm, blades set at around 30 degrees which throw away excess soil efficiently, and those compaction rollers that work together to firm things up properly. A recent look into agricultural equipment design from MDPI back in 2023 found something interesting about these machines. They reported that when working in sandy ground conditions, the trench depth stays stable about 86.7% of the time. Not bad for what farmers need in their fields.

How Hydraulic Systems Enable Precision in Ditch Lining

Hydraulic actuators regulate blade penetration and mold pressure, allowing operators to adjust forces between 15–20 MPa. This adaptability compensates for variations in soil density and maintains a ±5 mm tolerance in liner thickness, even on slopes up to 25°.

The Role of Conveyor and Molding Units in Continuous Liner Formation

A conveyor delivers pre-mixed concrete into the molding chamber at speeds of 0.5–2 m/min. Inside, vibration plates compact the material to 92–95% density. Real-time sensors detect voids and automatically adjust the feed rate to prevent structural defects.

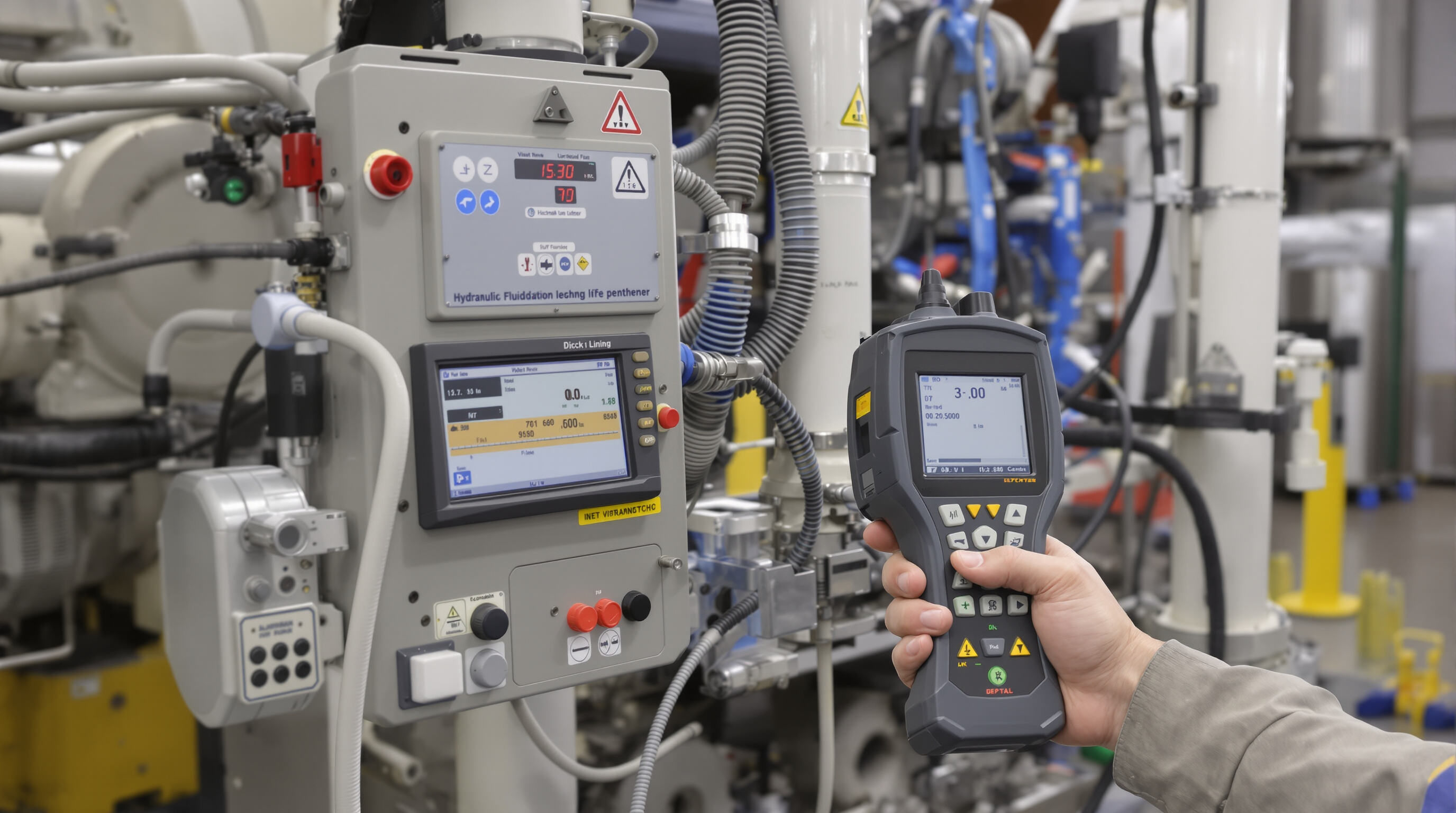

Integration of Control Panels for Real-Time Operational Monitoring

Modern control panels consolidate data on hydraulic pressure, conveyor speed, and slope angle into a single interface. When operational deviations exceed 8% of preset values, alarms alert operators, reducing error-related downtime by 40% (MDPI, 2023).

Pre-Operation Safety Checks for the U Shape Ditch Lining Machine

Inspecting Hydraulic Fluid Levels and Hose Integrity

Always check the hydraulic fluid before starting up anything heavy duty equipment. Make sure it's at the level specified by whoever made the machine, and take a good look at those hoses too. Are there any cracks? Bulges? Leaks anywhere? Running low on fluid isn't just inconvenient - it actually causes pump cavitation problems down the road. And if those hoses are damaged in any way, we're talking about serious risks like pressure drops or total system failure. Walk through the whole setup from the pump right out to where the actuators connect. Take note of any grime or residue building up around those connection points because that stuff matters. If something looks even slightly off, get it replaced fast. We're not kidding around here either. According to BLS data from 2022, nearly one out of every seven construction equipment accidents has something to do with hydraulic system failures.

Verifying Electrical Connections and Emergency Stop Functionality

Grabbing a multimeter helps spot problems in electrical conduits like loose connections or signs of corrosion before they become major issues. At every control station, technicians should press those emergency stop buttons just to make sure everything cuts off properly from both motors and hydraulic systems when needed. Restarting after stopping shouldn't happen by accident either so most setups require someone to manually turn a key first. This safety measure stops machines from suddenly coming back online while workers are still nearby doing repairs. Statistics show that around one out of four workplace electrocution incidents actually stem from faulty wiring or electrical failures somewhere on site.

Confirming Track and Wheel Stability on Uneven Terrain

Before starting work, check what kind of ground we're dealing with here. If the slope goes over 5 degrees, those stabilizing jacks need to go down for safety. Grab some calipers to measure how much the track pads are deflecting, then spin each wheel to make sure they turn smoothly without any wobbling issues. Getting this right matters because loose treads or axles that aren't lined up properly can lead to serious slippage problems when pushing concrete through, particularly bad news if the ground is damp or wet. Don't forget to run some weight distribution checks first thing too. Put those calibration weights in place and see how everything balances out before actually loading up with materials for the job.

Ensuring Proper Alignment of the Molding Chamber Before Startup

Use cross-hair laser levels to verify the molding chamber is perpendicular to conveyor tracks. Misalignment exceeding 2 mm can lead to concrete seepage or uneven liner walls, compromising structural integrity. Perform dry runs and adjust chamber height to match excavation blueprints, avoiding strain on hydraulic lifts.

Step-by-Step Operational Procedure for the U Shape Ditch Lining Machine

Starting the Engine and Initializing Hydraulic Pressure

Let the diesel engine run for around 3 to 5 minutes while idling before doing anything else. Keep an eye out for any strange shaking or unusual smoke coming from the exhaust pipe. When it comes time to bring the hydraulic system online, do so slowly and watch those pressure gauges closely. Most operators find that waiting until the pressure settles somewhere between 2000 and 2500 psi works best according to what OSHA recommends these days for safe hydraulic operations. Mechanics who follow this cold start routine instead of jumping right into heavy work report about 18 percent less wear on components over time. Makes sense really, since giving everything a chance to warm up properly just extends equipment life in general.

Engaging the Conveyor System with Pre-Mixed Concrete Supply

Load pre-mixed concrete into the hopper, maintaining a 65–75% fill level to avoid overflow. Begin conveyor operation at 50% speed, synchronizing with the auger to ensure steady flow. Verify that the slope angle adjustment mechanism aligns with the ditch gradient before increasing speed.

Adjusting Molding Speed Based on Soil Conditions and Gradient

| Soil Type | Recommended Speed | Liner Thickness Adjustment |

|---|---|---|

| Sandy | 1.2 m/min | +10% base thickness |

| Clay-rich | 0.8 m/min | -15% to prevent cracking |

| Gravel mix | 0.5 m/min | Reinforced side compaction |

Reduce speed by 20–40% on slopes exceeding 15° to maintain stability, as faster operation increases collapse risks by 32% (Geotechnical Engineering Journal 2024).

Monitoring Liner Thickness and Surface Finish in Real Time

Laser-guided sensors monitor liner thickness, triggering alerts for deviations beyond ±5 mm. Adjust hydraulic press force via the control panel when needed. Address surface flaws such as air pockets or ridges immediately by reducing conveyor speed and applying manual trowel corrections.

Shutting Down the U Shape Ditch Lining Machine After Shift Completion

Start by turning off the hydraulic system first and wait about 90 seconds for any leftover pressure to fully drain out before killing the engine. After running the machine, check both the molding chamber and conveyor belt thoroughly. Any hardened concrete should be cleaned off within half an hour or so to stop it from sticking permanently, as recommended in those NCMA maintenance docs from last year. Don't forget to lock all control panels securely and unplug the battery terminals too. This helps cut down on potential fire risks, especially important if there's dust buildup around electrical components.

Common Operational Hazards and Risk Mitigation Strategies

Pinch Points and Moving Parts: Protecting Workers Near the Molding Zone

The molding zone contains multiple pinch points where rollers, gears, and conveyors interact. According to a 2023 OSHA analysis, 23% of construction equipment injuries result from unguarded moving parts. Effective mitigation includes:

- Installing interlocked barrier systems that stop operation when access doors open

- Using laser proximity sensors to detect personnel within 12 inches of danger zones

- Holding daily safety briefings with site-specific hazard maps

Teams using infrared motion detection systems reported a 41% reduction in contact incidents compared to those relying on mechanical guards (Ponemon 2022).

Managing Overheating Risks in Prolonged U Shape Ditch Lining Machine Use

Operating above 90°F increases the risk of hydraulic fluid breakdown, with viscosity dropping 18% per 15°F rise (Fluid Power Institute 2023). To manage heat:

- Install real-time temperature sensors on pumps and valves

- Program automated cooling cycles every 45 minutes

- Conduct oil analysis every 250 hours to detect thermal degradation

Sites using thermal imaging tools reduced overheating-related downtime by 63% compared to visual inspections.

Preventing Concrete Blockages in the Feeding Mechanism

Inconsistent aggregate size causes 72% of blockages in U-shaped liner production (Concrete Products Association 2023). Prevention strategies include:

- Fitting vibratory sieves to remove debris larger than 3/4"

- Maintaining a minimum 45° hopper angle for smooth material flow

- Programming augers to reverse every 90 seconds during mixing pauses

Operations using laser-guided aggregate analyzers at feeder entries saw 89% fewer blockages than those using manual screening.

Equipment Safety and Maintenance Best Practices for Longevity

Proper maintenance of your U Shape Ditch Lining Machine is essential for safety and longevity. A structured maintenance plan prevents unexpected failures and can reduce repair costs by up to 40% (Gregory Poole 2025). Below are daily, weekly, and monthly routines, along with insights into predictive maintenance trends.

Daily Cleaning and Residue Removal from the U Shape Molding Die

Begin each shift by removing hardened concrete and debris from the molding die using non-abrasive tools. Buildup exceeding 5 mm can distort liner dimensions and lead to rework. For tough residues, apply biodegradable cleaning agents approved by the manufacturer.

Weekly Lubrication of Chains, Tracks, and Hydraulic Joints

Lubricate pivot points and hydraulic cylinder joints every 50 operating hours with high-temperature grease suitable for heavy machinery. Focus on track rollers—improper lubrication contributes to 23% of premature track failures. After lubrication, verify alignment to prevent uneven wear.

Monthly Inspection of Wear Plates and Replacement Scheduling

Inspect wear plates, bushings, and hydraulic cylinder rods every 150 operating hours. Use feeler gauges to measure component gaps, replacing parts when tolerances exceed 0.8 mm. Apply color-coded tags—red for immediate replacement, yellow for monitoring—to improve inventory tracking.

Trend Analysis: Predictive Maintenance Adoption in Ditch Lining Operations

Progressive operators now deploy IoT vibration sensors and hydraulic fluid spectrometers to predict bearing failures 200–300 hours in advance. Research shows predictive maintenance reduces unplanned downtime by 67% compared to reactive approaches. Integrate historical repair data to refine replacement schedules and extend equipment life.

FAQ Section

What is a U Shape Ditch Lining Machine?

A U Shape Ditch Lining Machine is specialized equipment used to construct ditches with U-shaped liners, typically in farming or construction sites to manage water drainage or irrigation.

How does the hydraulic system in the machine work?

The hydraulic system regulates blade penetration and mold pressure to adapt to different soil conditions, ensuring consistent liner thickness and precise operation.

Why is pre-operation safety checks important?

Pre-operation safety checks are crucial to identify and prevent potential hazards, such as hydraulic or electrical failures, which could lead to system failures or safety incidents.

What are common operational hazards for this machine?

Common hazards include pinch points from moving parts, overheating risks, and concrete blockages in the feeding mechanism.

Why is regular maintenance crucial for the machine?

Regular maintenance ensures the longevity and safety of the machine, preventing unexpected failures and reducing repair costs significantly.

Table of Contents

- Understanding the U Shape Ditch Lining Machine and Its Core Components

- Pre-Operation Safety Checks for the U Shape Ditch Lining Machine

-

Step-by-Step Operational Procedure for the U Shape Ditch Lining Machine

- Starting the Engine and Initializing Hydraulic Pressure

- Engaging the Conveyor System with Pre-Mixed Concrete Supply

- Adjusting Molding Speed Based on Soil Conditions and Gradient

- Monitoring Liner Thickness and Surface Finish in Real Time

- Shutting Down the U Shape Ditch Lining Machine After Shift Completion

- Common Operational Hazards and Risk Mitigation Strategies

- Equipment Safety and Maintenance Best Practices for Longevity

- Daily Cleaning and Residue Removal from the U Shape Molding Die

- Weekly Lubrication of Chains, Tracks, and Hydraulic Joints

- Monthly Inspection of Wear Plates and Replacement Scheduling

- Trend Analysis: Predictive Maintenance Adoption in Ditch Lining Operations

- FAQ Section