Ukubuya Ngendlela Umsebenzi wokulingana nge-U kanye nezinqawatha ezinhloko

Imigqamisa Eziphambene neqondo le-Machine ekuhlakweni kwe-Ditch Lining Machine ephatheniwe ngokushesha

I-U Shape Ditch Lining Machine inemigqamisa yamandla yezilika enkulu kanye neqondo lokuhamba kwezimbini ezikwakhiwa ukuvikela ubude obufanayo ngemva kokuhamba. Kunezinqawatha ezinhloko zalo mhlaba: kukhona le-mold die enokuthola ubude obuphela ku-300 mm, izibhobho ezisetiwe ngokupelile ku-30 izinyangeni ezingena ngokushesha kwezitshalo ezinkulu, kanye nezinqawatha zokugcina ezisebenza ngokwengeza ukugcinwa kahle. Kunesicatshulwa esisha esikhokhwe kwiqondo lezilwanyana zokulandela kwa-MDPI endulo ya-2023 ethile ngokuhamba kwalo mhlaba. Babhalile ukuthi xa kusebenzwa emhlabeni ongqamileyo, ubude bokuhlaka bube ngokwesibonelo kakhulu kungu-86.7%. Akuyona into encaneyo ethanda ukulandela kakhulu ngabantu basebenzisa izitshalo.

Yini Imigqamisa ye-Hydraulic Iyenza Ukucaciswa kumhlaka wokulandela

Izinkiniso zokugcinwa kwehlathu zokugcina ukufakwa kwehlathu nokugcinwa kwezintambo, kuvumela abasebenzisi ukuguqula amandla phakathi kwe-15–20 MPa. Lokhu kwenza ukuba kudingekile kwehlukahluka kwegatya kwezitshintsha futhi kugcinwele ukulinganisa kwezintambo kwe ±5 mm, noma kizindlela ezingama-25°.

Indima Yezinto Zokulayisha Nezinto Zokumiswa Kwekwekisa Ukumiswa Okuphelele kwezintambo

Isitayela sokulayisha sikhulisa ikonkreti evela ngaphakathi kwekhambini lokumiswa ngemizuzwana ye-0.5–2 m/min. Ngaphakathi, izinhlobo zokuthintwa zokugcina leli khanda ku-92–95% egatya. Izinhlobo zokuhlelo ngokushesha zithola amakhawula futhi ziguqula ngokuzenzakalelayo ukuguqula ukukhishwa ukuze akuvunyelwe ukungcono kwekhathile.

Ukuxhumana Kwezinhlobo Zokontrola Ukulandelela Ukusebenza Ngokushesha

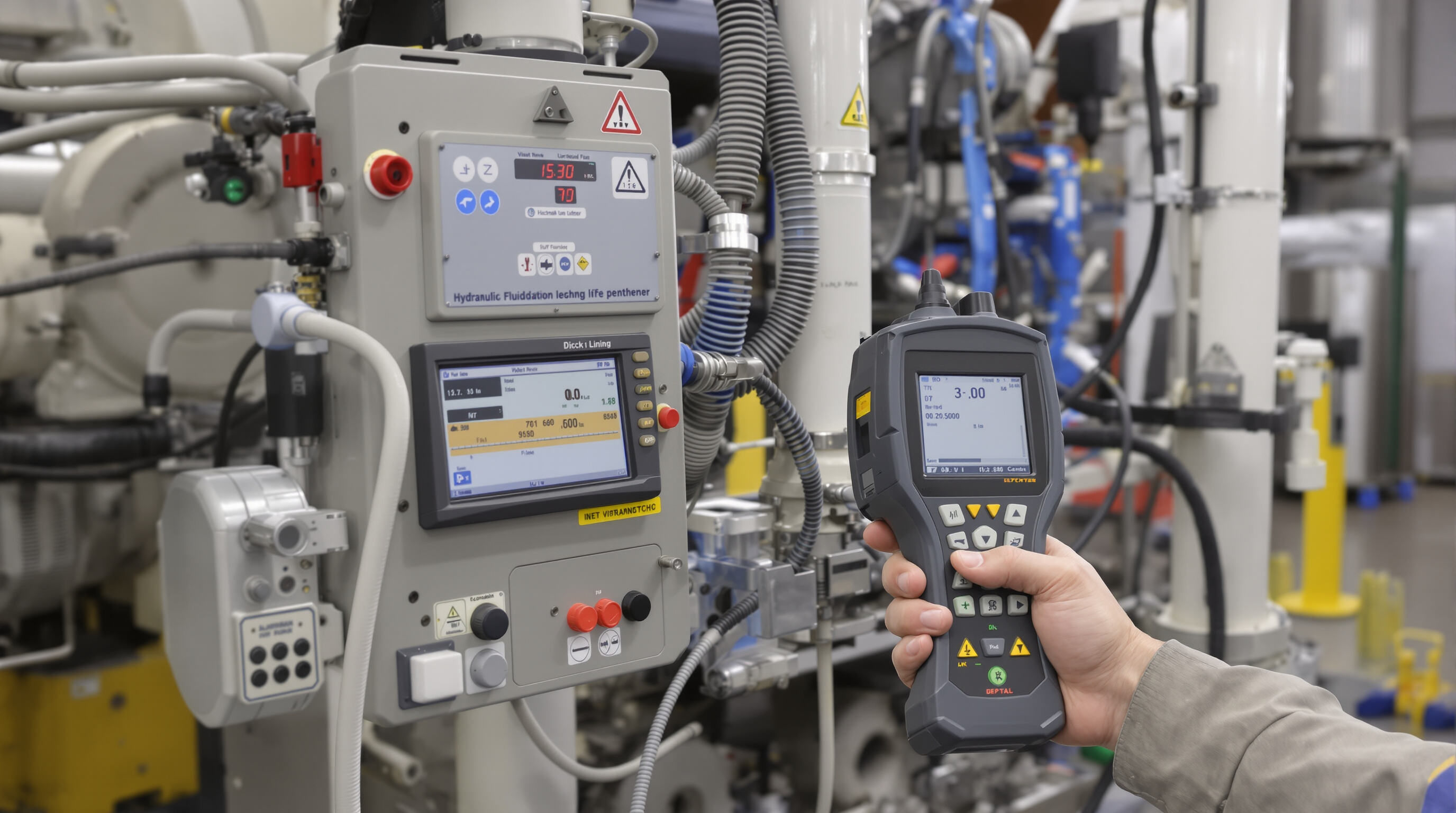

Izinhlobo zokontrola eziphetheni zokuxhumana idatha malunga nokugcinwa kwehlathu, isendvlo sekhathule, futhi kizindlela ngokunguqu kwekhathule. Xa kwehlukahluka kwekusebenza kungaphezulu kwe-8% yamathuba atholakale, izimpiyo zokuxhumana abasebenzisi, ukuthula kwezinsuku zokusebenza ngama-40% (MDPI, 2023) .

Imigomo Yokuhlinzeka Ngaphambi Kwekusebenza Kwemashini Yokumiswa U Shaped Ditch

Ukuhlola Imali Yezimoto Nezikhululo Zokugcinwa Kwezinhloso

Qaphela ukulola imali yezimoto kabefile uma uqala izinhlobo zokusebenza ngokukhulu. Sicela ubheke ukuthi yisiphi isimo esikhombiswe ngu- manufacturer wemashini, futhi uyibheke kahle le zinhloso nase. Ingabe kukhona amaphansi? Amabhulugi? Kuphi ukulala? Uma kungena kakhulu imali, akuyona kuphela okungcono - kodwa kuthinta iphampu ngokunguqulindlela. Futhi uma le zinhloso ziphathelene noma yikuphi indlela, sigatsha ngokuphelele kwezindleko eziningi njenge- pressure drops noma ukuphulwa kweqondo elide. Igcine ukuphambuka kweqondo kule qondo kusukela kwi-pump kuya kapho kubekwe amaphampu. Sicela ubheke futhi ukuthi kukhona amathotho noma amafutha apholile kuzo zikhawululo zokuxhumana nazo kuba le nto inesibonelo esikhulu. Uma kukhona okufanayo okuthi kunguqu ngokushesho, sicela uyishintshelwe. Asikwazi ukuthi kunguqu ngokushesho lapho. Ngokwesicelo se-BLS kusukela ku-2022, lobunye bokuqala kwezikhulu zokusebenza kwezokudla kumele kuthintekwa ngokuphulwa kwezinhlobo zezimoto.

Ukuqinisekisa Imisango ye-Electrical kanye ne-Funksheni ye-Emergency Stop

Ukuhokelela kwi-multimeter kusiza ukutholakala imimpilo ngokwezindleko zokuxhumana nezindleko eziyinkimbinkimbi noma imithi yokuphula ngaphambi kokuba kungcono. Kuzo zonke izindawo zokulawula, abasebenzisi kufanele bawubhale izibhobho zokumisa ngokuphawula ukuqinisekisa ukuthi konke kugcina ngempela kusuka kuma-motors kanye nezinhlelo zokushusha uma kudingekile. Ukuqala kabusha ngaphambi kokuthi kungashintshelwe ngendlela yokuthi kungcono ukuthi kubekwe ukuthi umntu ubhale ikliti yokuqala. Le ndlela yokuphepha iyamisa amashini ukuthi ayiphume kabusha ngokuphawula xa abasebenzi bangeziwe kakhulu ekwenzeni iziphiwo. Izibonelo zithi ukuthi umuntu engu-1 ku-4 wezindleko zokuphulwa kwe-electrocution ekuhlaleni kwendzawo zisuka kwi-wiring engalunganga noma imiphumela ye-electrical esibeni.

Ukuqinisekisa Ubunyakanye be-Track kanye ne-Wheel kumaqondo amaningi

Ngaphambi kokuqala ukusebenza, hlola ukuthi yini leli hlangothi ethi sithola lapha. Uma umphumo oguqukayo phezulu kwezingu-5, lezi zikhasi zokuthutha kufanele zilande kahle ngokuphelele. Bheka amaphakwe aphakathi ukuze uthakathelwe kanjani ukuthambwa kwemilenze, bese ubhalele yonke intambo ukuze uqinisekise ukuthi zihamba ngokuzuzwe noma ukungaphambelana. Kukhona ukuthi kumele kube yini le nto ngokuphelele kanti kungaphansi kwezindlela eziqinileyo noma izinkawu ezingaxhunyiweyo ngokuphelele zingase kuthiwe ukuthambwa okukhulu xa kuthiwa ukuthambwa kwekankamba, kudinga kakhulu uma leli hlangothi ligcwele noma libovu. Usikhuthi ukwenza amavivinyo okwahlisa ubunzima ngaphambi kwehlanga. Faka lezi zindlela zokuthakatha kusitsha bese uhlale ukuthi yini indawo etholakala ngayo ngaphambi kokuthiwa amagqunywe athathwe kusitsha.

Ukuthiwa Kumele Kuthuthwe Ngokuphelele Kwekamelo Yokwakha Ngaphambi Kokuqala

Sebenzisa imilaseri ye-cross-hair ukuqinisekisa ukuthi ikamelo yokuqina liphakathi kwezindlela zokulayela. Ukungqondakala okungaphezulu kwe-2 mm kungavumela ukulayela kwekankalu noma izindlela ezingahlukile, kubangelwa ukuphelelwa kwezinhlobo. Qala izinyathelo ezimvambo futhi ushintshelwe inqanawe yekamelo ukuthi ikhonge amadwele wezokulayela, ukuvikela ukuthintwa kwezindawo zokulifta izihlangothi.

Umthodi Wokwenza Okuqondileyo we-Machine U Shape Ditch Lining

Ukuqala i-Injini futhi ukuqala i-Hydraulic Pressure

Vumelana ukuba i-diesel engine ikhasa ngokungenakuliwa kwa-3 ku-5 imizuzu ngaphambi kwenye into. Hlala uqaphela ukuba kukhona ukuphenduka okungcono noma i-smoke engcono ekapheleni. Uma ufika ekubekeni i-hydraulic system kuvulekile, yenzi ngokomaluleke futhi uqaphela kakhulu amaphressa ayi-gauges. Abasebenzisa kangaka babona ukuba kubalulekile ukulinda ukuba i-pressure ikhona phakathi kwe-2000 ne-2500 psi futhi oku kuyindlela OSHA ibonisa ngokwamanje ngokuphepha kwezinyathelo zokusebenza kwezinhlobo zokulayisha. Abamekhaniki abasebenzisa le ndlela yokuqala esibhakabhakeni ngokugcwele kwezinyathelo ezinkulu babonisa ukuba kukhona ukungcola kwezinto ngokungenakuliwa kwe-18%. Kuyindlela engonakali futhi, ngisho noma unike amandla aphelele ukuba ikhasa kuvuleke kuholela ukuba izinto zibe nendawo ephakeme.

Ukuqala kwe-Conveyor System nge-Supply ye-Concrete ezi-mix

Faka i-concrete ezi-mix kwi-hopper, ukuhlola ukuba ikhona kwezibuko kwe-65–75% ukungabi nge-overfill. Qala ukusebenza kwe-conveyor kwe-50% yispeedi, ukuqanisa nge-auger ukuthi ubonakale ukuthi kune-flow engcono. Qinisekisa ukuthi imikhanismu yokulandela uhla lweqondo iyalingana neqondo labafile kabanga engeza ubukhawuleko.

Ukulandela ubukhulu bokudonsa ngokweminye yezindawo neqondo

| Uhlobo lwesithathu | Umbala othuthukisiwe | Ukulandela ubukhulu bokudonsa |

|---|---|---|

| Isandla | 1.2 m/min | +10% ubukhulu bwebhokisi |

| Inhlukwane | 0.8 m/min | -15% ukuvikela ukugcwala |

| Isambane sedlula | 0.5 m/min | Ukugcwalisa olwalweni olunxelene |

Lola ukukhula nge-20–40% kumaqheke aphakade 15° ukuvikela ukulawulwa, ngokuba ukusebenza ngokusheshayo kwenza amathiselwe kwehlukahluka nge-32% (IsiJornali seJiniyela Yezokwelapha 2024).

Ukukhombisa Ubukhulu Bekhawunti Nokupelwa Kwesihlandlo Ngokwesicelo

Izinhloso eziguqwayo zelaseri zikhombisa ubukhulu bekhwankanti, zivalela izimfihlo xa kuhambisana ngaphezulu kwe±5 mm. Shintshela inqanawa yesiphelo sehydraulic ngekhontrol panel uma kudingekile. Thintela amakhawunti aphansi njengezindlela zokugcwa noma amaqhinga ngokushesha ngekuhlanisa isivinini sokugcwalisa futhi usebenzisa ukusebenza kwesibhande.

Ukuvula Imikhombandlela D-shaped Ditch Lining Machine Emuva Kwesikhathi Samasheshi

Qala ngokuvula isisitemu solayithela kwanje udlale ngemizuzwana engu-90 ukuze wonke amandla esidlule ayisile kabusho bese uvule injini. Emuva kokusebenza kumakine, hlola kabusho ikamelo yokuvela nokweba yokuqhubela phambili. Konke ikonkreti esibekile kufanele silahlwe ngemva kwamazwakatho amaningi noma ngokuphephethwe ukuvikela ukuthi akhanye ngokudala, njengoba kuchazwe kakhulu kuma NCMA kwekho kuleli ndatshana. Ceba ukulungisa konke amaphaneli wokontrola ngendlela ecacile futhi ukuvula amaqelelo yebetheli nangaphezulu. Lokhu kusiza ukuthi kuthintwe amathuba okwandisa ukungcola, kudingeka kakhulu lapho kunezindleke zokuphutha emaklinikeni yezinhlelo zokuxhumana.

Izindleko Zokusebenza Futhi Izindlela Zokulungisa Izingozi

Izindawo Zokugcina Nezinto Ezihamba: Ukuvikela Abasebenzi Ngemva Kwesicathami Sokuvula

Isicathami sokuvula sineminye imicabango yezindawo zokugcina lapho izinyathelo, izigithe, nezicathamiro zihambelana nazo. Ngokwesicelo sase 2023 sika OSHA, 23% yezithwala eziphumelela kumakina yezokudla zisulela kumaqhubiso amahhovisi amahhovisi. Izindlela zokulungisa ezifanele kuzivumelana ne:

- Ukufaka imikhawulo ye-interlock esikhundla inqumatha lapho izindlu zokungena ziphume

- Ukusebenzisa izinhloso zokwethulwa ze-laser ukuthola abantu kumathela 12 inch esimweni esibangelwa

- Ukugcina izindaba zokuphepha ngemva yesikweletu ngezindawo zokubangelwa

Imithi ebalulekileyo esebenzisa izinhloso zokwethulwa ze-infrared izingenisa ukuncipha kwezinto eziphikisanayo umkhawulo wokunciphisa 41% kunazo ebalulekileyo esebenzisa imikhawulo yesimiso (Ponemon 2022).

Ukuphatha Imiphumela Esiqinileyo kwiindlela zokusebenza zokulayisha i-Machine Ditch enye kwezinto eziningi

Ukusebenza ngaphezulu kwe-90°F ikhathaza ukuthi ifluyidi yesithuthiwe liyashisa, ngeviscosity ezingenisa 18% ngalokhu 15°F (Fluid Power Institute 2023). Ukuphatha ukweshisa:

- Faka izinhloso zokulindela ukushisa kweqela kanye nezivalve

- Hlela ukushisa okuzenzekelayo kwezinyathelo zonke i-45 minethi

- Qhubekeka ukuvavanya iyojwana ngemva kwamathela 250 uhambo ukuthola ukushisa okuphoyiswe

Imithi esebenzisa izinhloso zokushisa kwezibonelo zingene ukunciphisa ukusebenza okweshisweni umkhawulo wokunciphisa 63% kunazo okusebenzisa ukubheka ngokulandela izibonelo.

Ukukhinda Ukuvimba kweBhlocke yesikhelo kumechanismi wokunyela

Izibuko ezingekombiso zokubanda kuzinzile 72% yezivimbo kumeqo weyindlela enesigxobo (Concrete Products Association 2023). Izindlela zokukhinda kuzo zilandela lezi zinto:

- Ukuze kwehlise amaqhinga athathu kwangaphambili

- Ukuqinisekisa ukuba kukhona ngaphantsi kwe-45° kwigqwa lokuvela ngendlela elula

- Ukuprograma kwamagqina ukuthatha isantya nganye kwezibini ukuya kwe-90 sekondi xa kuthatha isantya

Imisebenzi echazwe ngokusebenzisa i-laser-guided aggregate analyzers kwiindlela zokunyabela yabo yabhona amaphepha amancinci angu-89% ngaphantsi kwabasebenzisa ukuchonga ngendlela yokwenziwa.

Imali neNkqubo yokuphepha iMaliyo ngokusebenzisa iindlela eziphumelelayo

Ukuphepha ngokucophelela i-U Shape Ditch Lining Machine yakho kuyimfuneko yokuphepha kanye nokudala ngokude. Inqanawa yemaliyo yekhathazo iyavikela ukungabi naliphi na iphelo kwaye inokukhuphisa amathiphu okulungisa ngelixa engu-40% (Gregory Poole 2025). Ngasentla kunezithuba zokudlulwa, zokuhlisa kanye nezinye iindlela, kunye nembono kwiindlela zokukhangela iphelo.

Ukuculisa kanye nokususa amagqabi aphakathi kwe-U Shape Molding Die

Qala ngasikhathamo ngokususa ikonkreti enkulu nezilahla kusikhweleti sokudiliza ngokusebenzisa izicathami engenakuchithwa. Ukunqanqwa okuningi kune 5 mm kungavitha amathela kwezilahla futhi kungase kuthiwane kakhulu. Kumaqo amaningi, sebenzisa izinhlobo zokucula ezinhlelwe ngokwenhlanhla zokwenhlanhla.

Ukulubricate Ichaini, Iitheki, nezindawo zokuxhumana zokushisa ngoweeku

Lubricate izindawo zokugcina nezindawo zokuxhumana yasilinda ngemva kwamahora amavili angu-50 ngogu olunye olunamandla olunamandla olunamandla. Qh focus kwezitambwe zokugcina - ukulubricate okunguqulanga kungase kuthiwane kakhulu kwezitambwe zokugcina. Ngemva kokulubricate, qinisekisa ukuthi kuthiwe kahle ukuze kuvikele ukuthi kuthiwe ngokungafani.

Ukukhombisa Kwemathela Wezilahla Nokhetha Isicathami

Khombisa izilahla, izibhobho, nezindawo zokuxhumana yasilinda ngemva kwamahora amavili angu-150. Sebenzisa izinhlobo zokukhombisa ukuphakama kwamaphathi, khetha izinto lapho amathela amaningi kune 0.8 mm. Sebenzisa izithefule ezinemihla - yindlela yokuthiwa ngokushesha, yelule ukukhombisa - ukuze kuvikele ukuthi kuthiwe kahle.

Ukulungisa Isimo: Ukusebenzisa Isimo sangaphambili sokulungisa izinhlayiya kwezinyathelo zokulinda

Bazinyathi basebenzisa izinhlayiya zokuvula nezinhlayiya zokuchithwa kweyohlaya ukubonisa ukungcola kwezibhala ngemva kwezinsuku ezingu-200-300. Imicabango ikubonisa ukuthi ukulungisa ngokuzenzakalelayo kuncipha ukusebenza ngaphandle kwezimiso ngama-67% ngokulingana nezindlela ezingenakusebenzi. Sebenzisa imininingwane yesimiso ngalesi sikhathi ukulungisa izimpawu zokubuya futhi ukun extendinga ukusebenza kwamashini.

Isikhombisi Sokuqala

I-U Shape Ditch Lining Machine iyiphi?

Isithuthi sokulinda Ditch kweyohlaya U Shaped iyisithuthi esiyiswe ukudala amaditchi anezinhlayiya e-U-Shaped, okungenjalo kwezimali noma kwezokuhlinzwa ukulawula ukushushwa kwezimali noma ukulondoloza.

Yini indlela engcwele inqanawa yohlaya isebenza kulo rithisi?

Inqanawa yohlaya iyahlukisa ukungena kwesibhala nezinseke zokulaywa ukweselwa kwezintambo ezahlukene, ukubonza ukuthi kunezinhlayiya efanayo nezinseke eziphambene.

Kungani ukulungiswa kwezinyathelo ngaphambi kokusebenza kuyakho?

Imijulo yokuphepha ngaphambi kokusebenza kuyindlela yokubona nokuvikela izindlela ezingcono, njengokulahleka kwehha idroliki noma yokulahleka kwelekthrisithi, okungaba yindlela yokulahleka komsindo noma imiphetho yokuphepha.

Yiziphi izindlela ezingcono zokusebenza leli gciwane?

Izindlela ezingcono ziphakathi kuzo izindlela ezingcono zokugcina amandla, izindlela zokuphephethwa, nezindlela zokuvikela isankcazi ngaphakathi komsindo wokunyusa.

Kungani ukuphepha ngokudlule kuyindlela yokuphepha leli gciwane?

Ukuphepha ngokudlule kuyindlela yokugcina ukuphepha nokude kwegciwane, ukuvikela ukulahleka okungaphumeleli futhi ukunciphisa izindleko zokulungisa kakhulu.

Uhlu Lwezinto Eziqukethwe

-

Ukubuya Ngendlela Umsebenzi wokulingana nge-U kanye nezinqawatha ezinhloko

- Imigqamisa Eziphambene neqondo le-Machine ekuhlakweni kwe-Ditch Lining Machine ephatheniwe ngokushesha

- Yini Imigqamisa ye-Hydraulic Iyenza Ukucaciswa kumhlaka wokulandela

- Indima Yezinto Zokulayisha Nezinto Zokumiswa Kwekwekisa Ukumiswa Okuphelele kwezintambo

- Ukuxhumana Kwezinhlobo Zokontrola Ukulandelela Ukusebenza Ngokushesha

- Imigomo Yokuhlinzeka Ngaphambi Kwekusebenza Kwemashini Yokumiswa U Shaped Ditch

-

Umthodi Wokwenza Okuqondileyo we-Machine U Shape Ditch Lining

- Ukuqala i-Injini futhi ukuqala i-Hydraulic Pressure

- Ukuqala kwe-Conveyor System nge-Supply ye-Concrete ezi-mix

- Ukulandela ubukhulu bokudonsa ngokweminye yezindawo neqondo

- Ukukhombisa Ubukhulu Bekhawunti Nokupelwa Kwesihlandlo Ngokwesicelo

- Ukuvula Imikhombandlela D-shaped Ditch Lining Machine Emuva Kwesikhathi Samasheshi

- Izindleko Zokusebenza Futhi Izindlela Zokulungisa Izingozi

- Imali neNkqubo yokuphepha iMaliyo ngokusebenzisa iindlela eziphumelelayo

- Ukuculisa kanye nokususa amagqabi aphakathi kwe-U Shape Molding Die

- Ukulubricate Ichaini, Iitheki, nezindawo zokuxhumana zokushisa ngoweeku

- Ukukhombisa Kwemathela Wezilahla Nokhetha Isicathami

- Ukulungisa Isimo: Ukusebenzisa Isimo sangaphambili sokulungisa izinhlayiya kwezinyathelo zokulinda

- Isikhombisi Sokuqala